Overhaul Repairs Upgrades Valves

Overhaul / Repairs / Upgrades Valves

TPS team has multi skilled staff have many years of combined experience on repairing, modifications or replacements to equipment which is under performing. During site surveys and client discussions we can offer suggestions and recommendations to improve existing systems and processes.

All of our Engineers and Technicians have been fully trained by Fisher and Flowserve so you can rest assured that your equipment is in safe hands.

When it comes to repairs, we always offer OEM spares in the first instance and when necessary – and only with written client approval and agreement – we can supply non-OEM parts to speed up the repair process. We have full use of the system which gives us live prices and deliveries meaning we can provide the much needed quotes quickly and efficiently meeting our customers needs. We offer a full guarantee and warranty against faulty workmanship or materials.

Typical Valve Maintenance Routines

Non-repairable or unserviceable valves

Up to 90% of all valves are salvageable and may be overhauled at considerable savings when compared to purchasing a new unit. We can arrange collection and delivery of valves. The customer will be advised if, in the opinion of our Senior Workshop Engineering Supervisor, the valve cannot be repaired or may not be economical to do so or is likely to be unreliable or may be prone to poor operation at a future date. Such advice will be supported with a report together with our recommendations on a suitable like-for-like replacement.

Below are the typical stages of an valve overhaul at our workshop:

Initial Inspection and Review

Firstly the details of the valves and any instrumentation is noted down and loaded onto the system. We have a bespoke Valve Management Database where every job is loaded on to give real time updates of the progress of the valve as well as all the details of the valve.

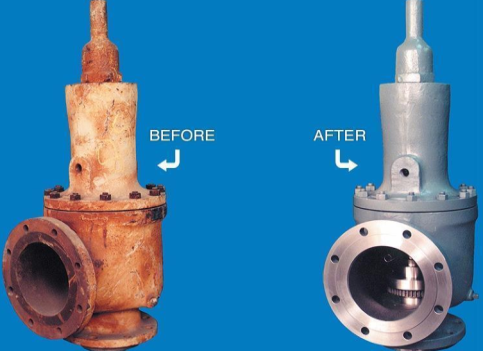

Shotblast and Paint

The valve will be completely shot blasted and cleaned up before being painted.

Reassembly

The valve will be rebuilt using all new soft spares and any new spares bought to return the valve to a working order.

Testing

With the equipment assembled its goes through the Testing Stage to ensure its working correctly and ready for service.

Final Check

This final stage ensures the valve meets the customers’ requirements and that it has been built back up to specification before signing the job off and the certification produced.

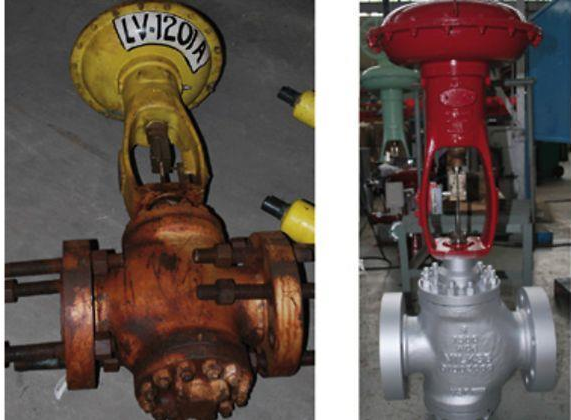

Trust TPS to transform any valve from scrap to better than new condition.

On arrival at the workshop, your valve is assessed before being stripped and inspected to produce a detailed report. Through a combination of advanced technology, enhanced materials and experience, TPS consistently repair and refurbish valves that are seemingly beyond economical repair to a standard which far exceeds the original valve’s performance.

Refurbish Your Coker Valves: An Economical Alternative

Sales & Service

• All Manufacturers (API 6A)

• Gate valves

• Kelly Valves

• Safety Valves

• Float Valves / IBOP’s

• Ball valves

• Orbit Drilling Valves

• Chokes

• Check Valves

• Manifolds (Gate Valve/Ball Valve/Plug Valve)

• Hydraulic/Pneumatic Actuators

• Mud Valves

• NACE Certification

Manufacturing Valves by our Canadian Partner

• 2”, 2 1/16”, 3 1/8” Ball Valves

• Quarter turn Hydraulic Actuators

• Linear Dual Acting Hydraulic Actuators

• 2 1/16” 3600 Check Valves

• 2 1/16” – 3 1/8” 3,000 -5,000 psi Chokes

• Kelly Valves (2 ⅞” IF to 6 5/8” RLH)

• One Piece Kelly Valve Saver Sub

(3 ½”IF to 4 ½”IF)

• Dart & Flapper Style IBOP

(3 ½”IF to 4 ½”IF) c/w Top Cap

Flanges & Spacers

• Companion Flanges

• Weld Neck Flanges

• Single/Double Studded Adapters

• Spacer Spools

• Adapter Spools & Adapter Flanges

Parts

• All Valve Components Manufactured to OEM Specifications.

• Non-Valve Components Are Manufactured Upon Customer Request and to Customer Drawings and Specifications.

• All manufactured parts are Made in Canada

.jpg)

.jpg)